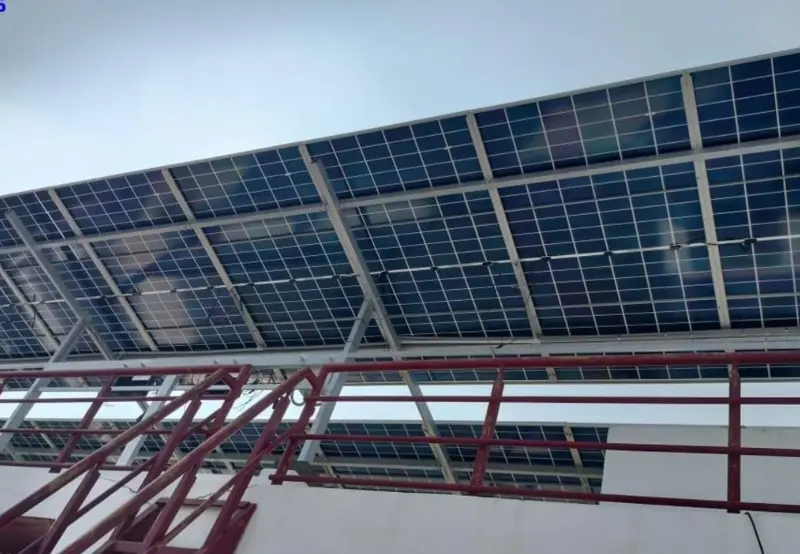

The global surge in silver prices is increasingly becoming a significant concern for the solar photovoltaic (PV) industry. Once a relatively small part of the cost structure, silver has transformed into a major component expense for solar cell and module manufacturers — with implications for production costs, panel prices and supply chain strategies.

Why Silver Matters to Solar Panels

Silver plays a crucial role in solar cell manufacturing. It is used in the conductive paste that forms the electrical contacts on PV cells, facilitating efficient flow of electricity from the solar absorber to the panel’s output terminals. Due to its excellent electrical and thermal conductivity, silver has long been the material of choice in this application.

Historically, silver accounted for a modest share of total panel costs. However, as global demand for solar power has expanded rapidly, the industry’s collective silver consumption has grown significantly. Projections suggest solar panel manufacturing is poised to consume a notable percentage of the world’s annual silver supply, driven by the widespread deployment of PV systems and ambitious clean-energy targets.

Record High Silver Prices Squeeze Solar Costs

In recent months, silver prices have reached record highs, climbing well beyond previous historical levels. In early 2026, silver traded above $108 (per ounce), a dramatic increase compared with average levels in prior years. This spike has substantially increased the cost of silver paste — which now represents a far larger proportion of total solar panel production costs than it did just a few years ago.

As silver accounts for an ever-larger share of input costs, solar manufacturers are facing tighter profit margins. Unlike labour or general manufacturing costs, raw material prices can shift rapidly in response to industrial demand, investment flows and supply-side constraints. Because solar panel prices have been under pressure from intense competition and tariff caps, manufacturers have limited ability to raise final prices proportionally.

Industry Response: Reducing Silver Use and Exploring Alternatives

The industry’s response to surging silver costs has been twofold:

1. Reducing Silver Usage (Thrifting):

Manufacturers are intensifying efforts to lower the amount of silver used per solar cell. Improvements in cell design, thinner conductive lines, and more precise printing processes can reduce silver consumption without significantly affecting electrical performance — provided these engineering changes are carefully implemented.

2. Exploring Material Alternatives:

Some leading solar producers have announced plans to trial or scale up use of base metals such as copper in place of silver. Copper substitutes offer lower material cost, but there are trade-offs in terms of conductivity and long-term reliability. Still, this shift reflects a broader industry willingness to innovate in the face of persistent raw material price volatility.

Wider Impacts on Solar Pricing and Deployment

Higher silver prices are adding cost pressure at a time when many PV manufacturers are already navigating competitive markets and slim margins. As input costs rise, there is a risk that:

- Solar panel prices may stop declining as they have for years, or could even increase modestly to absorb part of the material cost rise.

- Project developers may face higher upfront costs, particularly for large utility-scale installations where silver intensities remain material.

- Smaller manufacturers with less flexibility to innovate or secure alternative commodities may struggle to compete.

Some analysts argue that if high silver prices persist, the solar industry might experience a reshaping of its cost structure, with downstream costs shifting and more innovation around materials — including advanced metallisation methods and new cell architectures that minimise precious metal usage.

Long-Term Outlook

Despite present challenges, the solar industry continues to innovate. Research and development into alternative materials, continued improvements in cell efficiency and more strategic commodity planning are all part of how manufacturers are adapting. Industry experts note that quality does not have to be compromised even as silver usage is reduced — provided engineering and manufacturing processes are optimised.

In the broader view, the surge in silver prices underscores how renewable energy transitions are increasingly tied to global commodity markets. Silver’s dual role as both a precious metal and a critical industrial input reflects the complex dynamics shaping the future of solar manufacturing.